Supply Chain

WHAT FUJITSU ASPIRES TO BE

In its supply chain, the Fujitsu Group will achieve responsible procurement that embraces diversity and gives full consideration to human rights, the environment and health & safety.

GOALS FOR FY2022

- The Fujitsu Group will achieve responsible procurement in its supply chain.

To ensure that its major suppliers comply with the international standards for responsible procurement, the Fujitsu Group will obtain one of the following documents from its major manufacturing subcontractors and parts suppliers for its core products: (Target KPI =100%)

- KPI :

- A platinum or gold level of site recognition under the RBA Audit Recognition program

- Written consent with the Fujitsu Group CSR Procurement Guideline (equivalent to the RBA Code of Conduct)

- Promotion of supply chain diversity

We set supply chain diversity as our goal of Responsible Business and promote it globally. - Reduction of Greenhouse Gas (GHG) Emissions in Supply Chain

We requested our foremost suppliers to set the quantitative targets complying with an International Standard to reduce

GHG emissions.

Policy

The Fujitsu Group holds “Co-existence with Suppliers”, “Fair and Proper Evaluation and Selection of Suppliers” and “Promotion of CSR-Conscious Procurement Activities” as the tenets of its Corporate Social Responsibility (CSR) procurement policy, and conducts its global procurement activities accordingly.

In 2005, we formulated the "CSR Procurement Guideline” for CSR procurement and requested our suppliers in Japan and overseas to comply with that guideline. In 2018, we adopted the RBA(*1) Code of Conduct as the "Fujitsu Group CSR Procurement Guideline".

- (*1)[PRESS RELEASE] Fujitsu Joins EICC, a Global Corporate Social Responsibility Coalition (renamed as the Responsible Business Alliance (RBA) in October 2017)

https://www.fujitsu.com/global/about/resources/news/press-releases/2017/0329-01.html - Fujitsu Group Procurement Policy

https://www.fujitsu.com/global/about/procurement/policy/ - Fujitsu Group CSR Procurement Guideline (RBA Code of Conduct)

https://www.responsiblebusiness.org/code-of-conduct/

Structures for Promoting CSR Procurement & Periodic Reviews

Under the group-wide policy, the relevant departments in the Fujitsu Group collaborate regarding the promotion of CSR activities. In the area of procurement, the Global Supply Chain Unit works with the relevant departments in promoting socially responsible procurement activities by suppliers. The CSR promotion activities are targeted at our major suppliers, that is, the largest suppliers on a monetary basis and those who have ongoing dealings with Fujitsu.

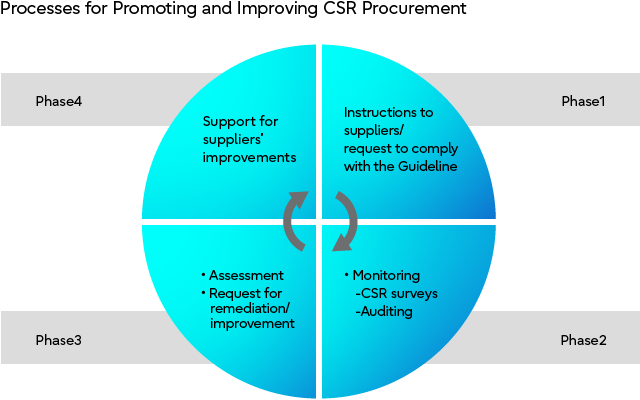

We initially clarify the compliance items through its CSR Procurement Guideline and then require our suppliers to undertake CSR activities. To confirm that these CSR activities are being fully implemented by suppliers, they are asked to respond to a range of surveys on topics such as green procurement, information security and Business Continuity Management (BCM).

The survey responses are analyzed and the results are returned to the suppliers as feedback. Where a supplier fails to meet Fujitsu’s standards, they undertake to make improvements. Where there is a particular need to check whether CSR activities are being fully implemented by a supplier, a CSR audit is conducted. Such suppliers are required to submit a remediation plan for any matters identified by the audit and Fujitsu works with the suppliers to make the necessary improvements. Fujitsu is continually improving its processes and promoting CSR procurement with the goal that ultimately CSR activities will be properly undertaken by suppliers and will become firmly entrenched.

Promoting Activities and Participation in Industry-standard Initiatives (RBA Membership)

The Fujitsu Group is a member of the Responsible Business Alliance (RBA), a global CSR alliance. As such, we give serious consideration to the RBA’s Code of Conduct and engage in socially responsible procurement with our suppliers and throughout our supply chain.

The Fujitsu Group also takes an active role in the programs and initiatives of organizations such as the Japan Electronics and Information Technology Industries Association (JEITA) and works to promote socially responsible procurement in the industry.

Addressing High-Risk Minerals

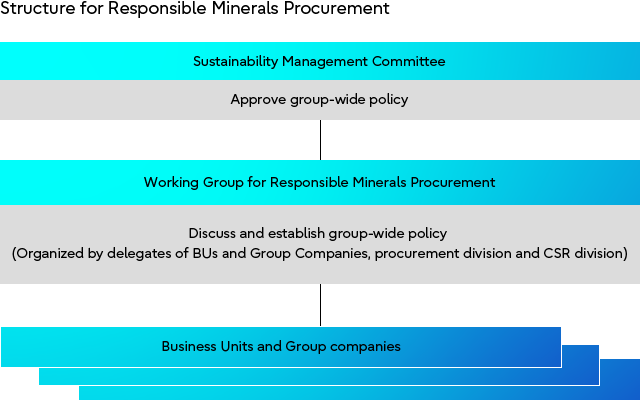

The policy of the Fujitsu Group is to exclude from its products, components and supply chain any minerals that give rise to conflicts (“conflict minerals”), or minerals that are at high risk of being associated with forced labor or human rights violations. (The Fujitsu Group identifies tantalum, tin, gold, tungsten and cobalt as high-risk minerals.) Fujitsu has also established a structure to ensure the transparency of procurement activities in the supply chain and the responsible procurement of minerals. This structure includes the relevant internal departments and operates under the jurisdiction of the Sustainability Management Committee (chaired by Fujitsu’s President).

- Fujitsu Group Policy on Responsible Minerals Procurement

https://www.fujitsu.com/global/documents/about/csr/procurement/Fujitsu_Group_Policy_on_Responsible_Minerals_Sourcing_v01.pdf

Surveys on High-Risk Minerals

As part of its due diligence, the Fujitsu Group conducts high-risk minerals surveys with reference to the “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas”. These surveys use the Conflict Minerals Reporting Template (CMRT) and Cobalt Reporting Template (CRT) developed by the Responsible Minerals Initiative (RMI).

- List of smelters checked in the surveys

https://www.fujitsu.com/global/documents/about/csr/procurement/2022 Smelter List.pdf

Reminders are sent to those suppliers who failed to respond to our survey by the due date. If survey responses reveal insufficient answers, suppliers are asked to resubmit their responses. Where customers indicate that a smelter is considered to be “risky”, we ask suppliers using that smelter to re-examine the nature of their dealings with the smelter.

While there have been no confirmed reports yet of smelters having any involvement with armed groups, we will continue to conduct programs aimed at identifying smelters and further increasing transparency in our supply chain.

Promoting Green Procurement

The Fujitsu Group has set out its basic approach to the environmentally sound procurement of components, materials and products in the Fujitsu Group Green Procurement Direction, and we are working with our suppliers to promote green procurement activities. One target for such activities is the reduction of CO2 emissions, and the Fujitsu Group is requesting that its suppliers, and their suppliers in turn, set targets and promote activities to reduce their CO2 emissions. In addition, we are asking our suppliers to conduct water risk assessments as a first step toward water resource conservation. We will continue to promote activities that reduce environmental impacts throughout our supply chain.

- Fujitsu Group Green Procurement

https://www.fujitsu.com/global/about/procurement/green/

Promoting Information Security Measures

Based on the “Cybersecurity Management Guidelines” issued in December 2015 by Japan's Ministry of Economy, Trade and Industry (METI) and the Information-technology Promotion Agency (IPA), the Fujitsu Group, along with its suppliers, has adopted the goal of “eliminating information security incidents”, and is continually implementing measures to prevent such incidents or recurrences. These measures include education, raising awareness, auditing and sharing information.

In recent years, there has been a significant increase in the commercial use of external services such as cloud computing and social media. There has also been a rapid increase in opportunities for the use of smart devices such as smartphones and tablet PCs. Since FY2020, there have been major changes to workplace arrangements to mitigate the spread of the COVID-19 pandemic, notably a rapid rise in teleworking (working from home). Regarding the risk of information leaks, it is necessary to prevent not only incorrectly addressed emails being sent by mistake and the theft or loss of PCs and smart devices, but also new kinds of risks such as in-house crimes and cyber terrorism. In this context, when the Fujitsu Group consigns work to suppliers, including those outside Japan, it promotes education and awareness by requiring the same standards of information security management and handling of personal information as it applies to its own operations. If any serious problem regarding information security is discovered at a supplier, or if the supplier fails to immediately implement corrective measures and no improvement is observed, Fujitsu will take steps such as reviewing its business relationship with the supplier.

Enhancing Supply Chain BCM

The Fujitsu Group sees the enhancement of Business Continuity Management (BCM) throughout its supply chain as essential to ensuring a stable supply of products and services in the event of major disasters or other unexpected contingencies. Accordingly, since FY2007 we have provided our suppliers with ongoing support to improve their BCM capabilities.

Fujitsu conducts an annual questionnaire-based survey of its suppliers on how they address BCM. This survey also covers some group companies that conduct their own procurement. We analyze the responses to the survey and then provide feedback to the suppliers and group companies. Since FY2014, we have been using a standard survey form developed by JEITA’s Materials Committee.

Fujitsu also conducts annual surveys of major solutions-related suppliers, analyzing the responses and providing feedback.

Communication with Suppliers

Business Meetings

Under the Suppliers' Performance Review (SPR(*2)) system, the Fujitsu Group holds management-level business meetings targeting its major suppliers. These meetings provide both direct feedback on the assessment results in an interactive format as well as explanations of Fujitsu’s business outlook and procurement strategy. The feedback provided at these meetings also addresses CSR topics, and suppliers whose efforts do not meet Fujitsu’s standards are asked to make improvements. Fujitsu also carries out assessments of solutions-related suppliers and provides the results of those assessments as feedback to the major suppliers.

- (*2)Suppliers’ Performance Review: A program developed by Fujitsu that assesses the performance of procured goods and the basic profile of enterprises in terms of quality, technology, price, supply and CSR.

Fujitsu ActivateNow Partner Summit

The Fujitsu Group has held events for its suppliers since FY1997. We have held our global flagship event, Fujitsu ActivateNow Partner Summit(*3), in an online format since FY2020. Senior executives and the heads of business groups give overviews of Fujitsu’s business direction, and the Executive Vice President responsible for purchasing explains Fujitsu’s procurement strategy. This event is also an opportunity to present certificates of appreciation to partners who make exceptional contributions to our business and to further strengthen our partnerships with suppliers.

- (*3)Fujitsu ActivateNow Partner Summit: A reorganized event that replaced the previous Fujitsu Suppliers’ Reception and the Fujitsu Group Core Partner Forum.

Strengthening Procurement Compliance

Education by Procurement Divisions

The procurement divisions of the Fujitsu Group conduct training programs for their suppliers to disseminate awareness of CSR and ensure that procurement is socially responsible. In addition to CSR procurement and green procurement, training aimed at increasing awareness among procurement staff is also offered in the areas of risk management (BCM activities) and compliance with legislation such as the Subcontracting Law and the Worker Dispatching Business Law.

Supplier Compliance Line

The Fujitsu Group uses the Supplier Compliance Line as a channel to receive reports from suppliers regarding any actions that are potential or actual instances of non-compliance in our purchasing activities. Channels have been set up both internally and externally through which we can verify and investigate the facts of each report and respond quickly.

Fujitsu’s internal reporting standards prohibit any adverse treatment of its own staff making such reports or of staff from suppliers making the reports.

Our agreements with suppliers also include explicit provisions on the elimination of anti-social forces and other such groups with the aim of preventing harmful actions by such anti-social forces (and avoiding any encouragement of their activities). The Fujitsu Group, including its suppliers, will have no relationship whatsoever with anti-social forces.

- Supplier Compliance Line (Japanese only)

https://www.fujitsu.com/jp/about/csr/management/compliance/complianceline/

FY2021 Performance

CSR Surveys

- CSR surveys for major Japan Domestic/International suppliers (including Fujitsu and its group companies) : 560 companies

High-Risk Mineral Survey Results

- Fujitsu received responses from 89.2% of the suppliers surveyed.

- Smelters operated by 405 companies were checked, of which 269 were compliant with the RMI-certified Responsible Minerals Assurance Process (RMAP).

Promoting Information Security Measures

- Web surveys on the state of information security measures (July-Dec. 2021): 2,175 companies

- Audits on the state of information security measures (self-administered) (Nov. 2021-Mar. 2022): 277 companies

Enhancing Supply Chain BCM

Products:

- Surveys conducted (July-Oct. 2021): Approximately 790 companies / 1,630 locations

- Feedback provided (Nov. 2021): Approximately 790 companies / 1,630 locations

Solutions:

- Assessment feedback provided: Approximately 270 companies

Communication with Suppliers

Products:

- Business meetings held: 6

- Feedback provided (Nov. 2021): Approximately 790 companies / 1,630 locations

- Surveys conducted relating to SPR: 28 companies

Solutions:

- Partnership meetings held for information sharing, etc.: Approximately 270 companies